View from the scrap stacking section to the inspection station

View from the scrap stacking section to the inspection station

The Dortmund installation is of great strategic importance for thyssenkrupp Steel Europe: all steel strip undergoes thorough inspection before leaving the facility. The purpose of the installation is to inspect steel strip for faults and defects as well as to detect and remedy flaws. The steel strip can also be edge-trimmed, oiled and cuted. All of this is carried out by different machines: coilers are used to wind up and uncoil the up to 40 ton steel coil. From there, the start of the strip is transported to the welding machine where it is welded to the end of the last coil. At the inspection station, trained personnel using a wide range of measuring technology inspect the 1,700 millimeter wide strip. The sophisticated automatic system ensures seamless tracking of material and error detection. Cropping shears and edge trimming shears cut the strip to size. The installation also includes an oiling machine as well as devices to automatically mark and strap the coils.

When the installation first went into operation in the early 70’s, safety regulations were different than they are today. This has necessitated ongoing further development to keep the installation state-of-the-art and guarantee its long-term safe operation.

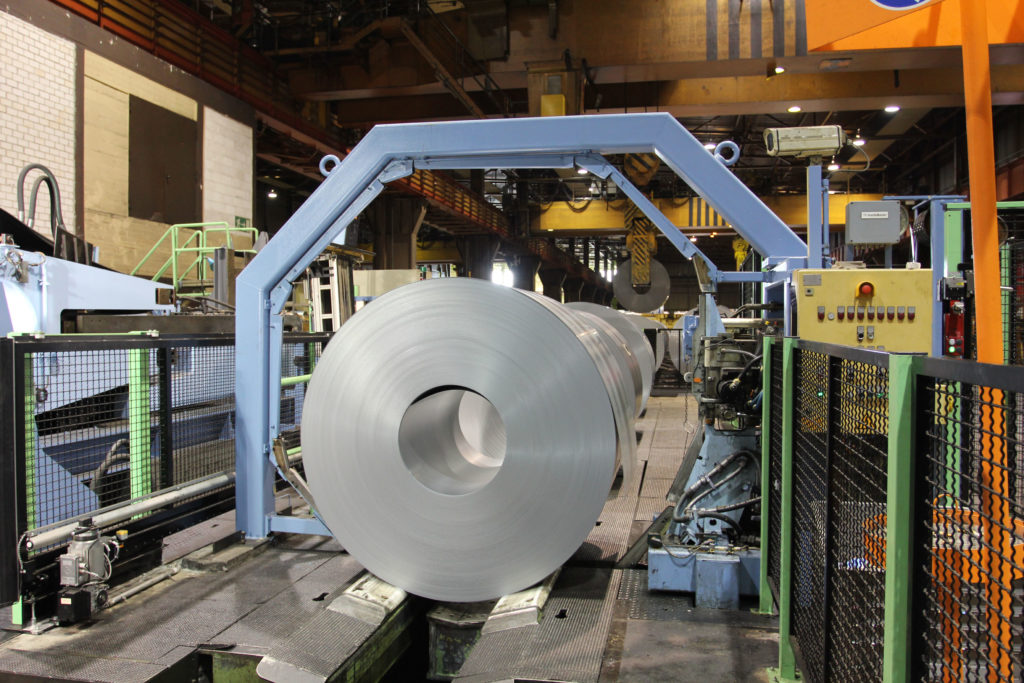

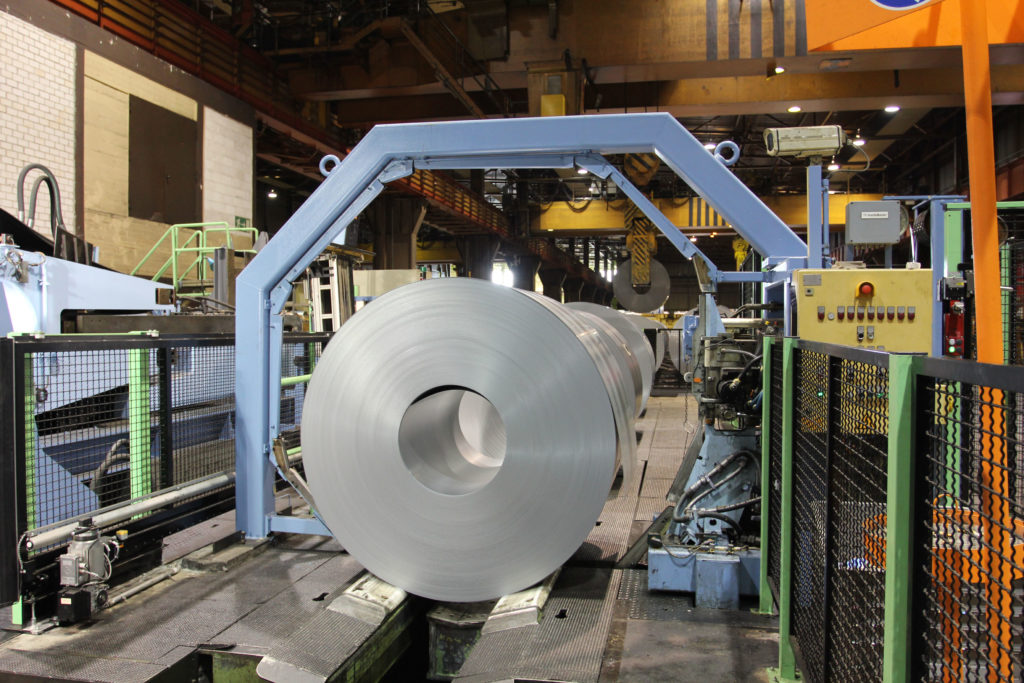

Walking beam transport system and coil strapping

The goal: greater functional safety while maximizing performance

Walking beam transport system and coil strapping

The goal: greater functional safety while maximizing performance

To determine the concrete modernization needs, Unitechnik and the thyssenkrupp divisions Production, Maintenance and Work Safety as well as the Professional Trade Association for the Wood and Metal Industries (BGHM) conducted a functional safety analysis of the technical installation. Depending on the detected hazard potential and technical needs, the installation was broken down into different safety sections. This served as the basis for Unitechnik's modernization concept for coil inspection line 2. Together with the high safety standard to be met, there was another parameter that defined the framework for the potential solution: the modernization measures were not to have a negative impact on the installation's performance values.

Safety and protection in all work areas

In addition to implementing electrical, mechanical and hydraulic safety equipment and devices, the concept also included modernization of all drive and control technology including a new supervisory control and data acquisition (SCADA) and human-machine interface (HMI) system.

Sliding gate separating two safety zones at the coiler

Automation: an important key to success

Sliding gate separating two safety zones at the coiler

Automation: an important key to success

In its 45-years of existence, the coil inspection line 2 was regularly modernized and new machines added. The challenge Unitechnik faced was consequently integrating components from a variety of manufacturers and different interfaces in the functional safety concept. Automation of what were previously manual work steps was an important key to success in this process. New measuring technology using laser light barriers, for example, automated the process of placing coils onto the coiler. Using transfer equipment, such as tables and conveyors, the strip is now transported to the welding machine without manual intervention. The straightening of the respective beginning and end of the strip in the welding machine is now also fully automatic.

Exit from the oiling machine to coiler

Ready for the next 20 years

Exit from the oiling machine to coiler

Ready for the next 20 years

thyssenkrupp Steel Europe profits from the modernization not only from shorter set-up times and a major reduction in the number of manual work steps but also from state-of-the-art functional safety technology. The modernization has secured the long-term and efficient operation of the installation.

Source: Wire and Tube News

View from the scrap stacking section to the inspection station

View from the scrap stacking section to the inspection station Walking beam transport system and coil strapping

Walking beam transport system and coil strapping Sliding gate separating two safety zones at the coiler

Sliding gate separating two safety zones at the coiler Exit from the oiling machine to coiler

Exit from the oiling machine to coiler