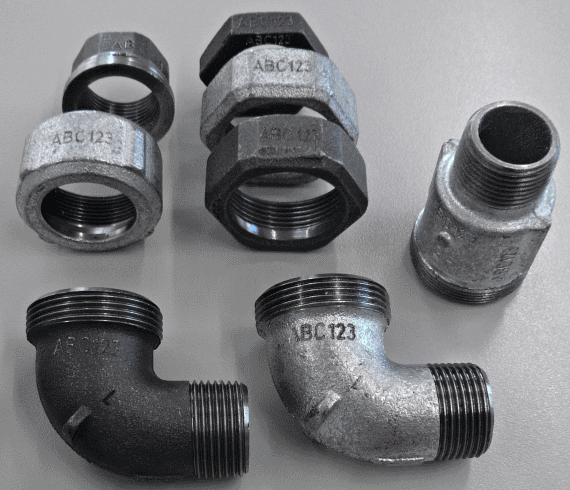

Durable marking of fittings © MARKATOR Manfred Borries GmbH

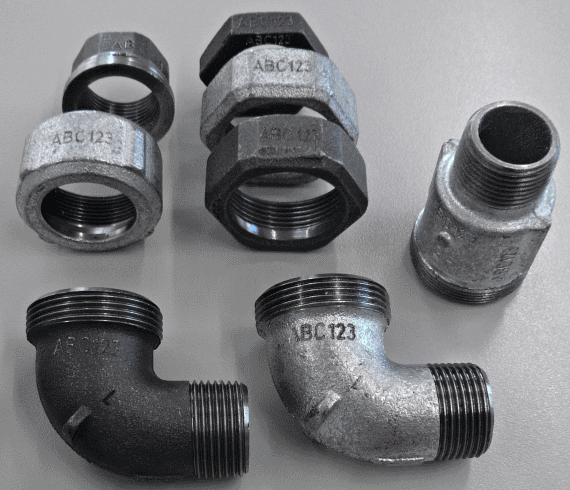

Durable marking of fittings © MARKATOR Manfred Borries GmbH

In the pneumatic and hydraulic industry sectors the battery operated and portable hand-held marking systems FlyMarker®, for big and small diameters, as well as table marking systems as for example the NetMarker® XL, mainly for small diameters are in use.

With the table marking system, it is very easy to adjust the marking on the work piece, using a fixture on the machine bench, provided by the customer. If the work pieces are out of steel, a magnetic prism fence has proven its worth. The marking itself takes place by an oscillating marking pin and is, due to the high quality mechanics of the marking system, very precise.

© MARKATOR Manfred Borries GmbH

© MARKATOR Manfred Borries GmbH

Compared to the table marking systems, the battery operated hand-held marking system FlyMarker® is very flexible and can also be used for big diameters. For this, the mobile dot peen marker can directly put on the work piece to be marked.

Due to the battery mode and the electromagnetic impact mechanism, the work piece can be marked cordless and without compressed air directly on-site. To mark small fittings and tube diameters, the battery operated and portable hand-held marking system can easily be mounted on the optional available column frame and can with this be used as a table marking system.

The programming can be done via the software which is self-explanatory and intuitive to operate. The marking file with for example a company logo, a part number or article number can be created very easy and can be checked via the preview function of the software before marking.

Due to the durable marking on the work piece, the traceability in the event of a complaint can be ensured. In the case of a warranty claim, the manufacturer can see whether it is an original part or a forgery. A marked article number on the fittings also makes the spare parts procurement and the warehouse allocation very easy.

Source: tube-tradefair