Efficient tool finishing with the new SF1-Automation

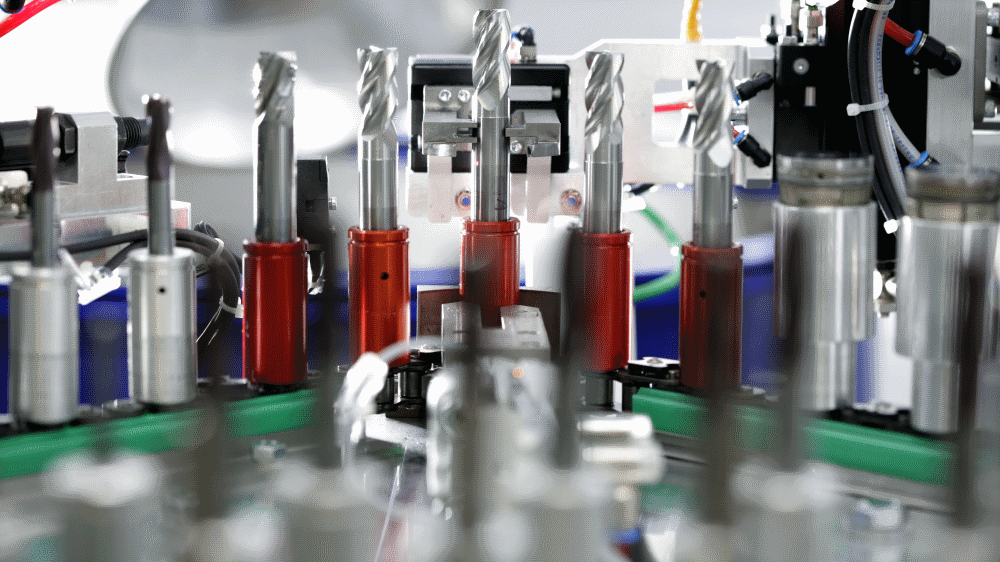

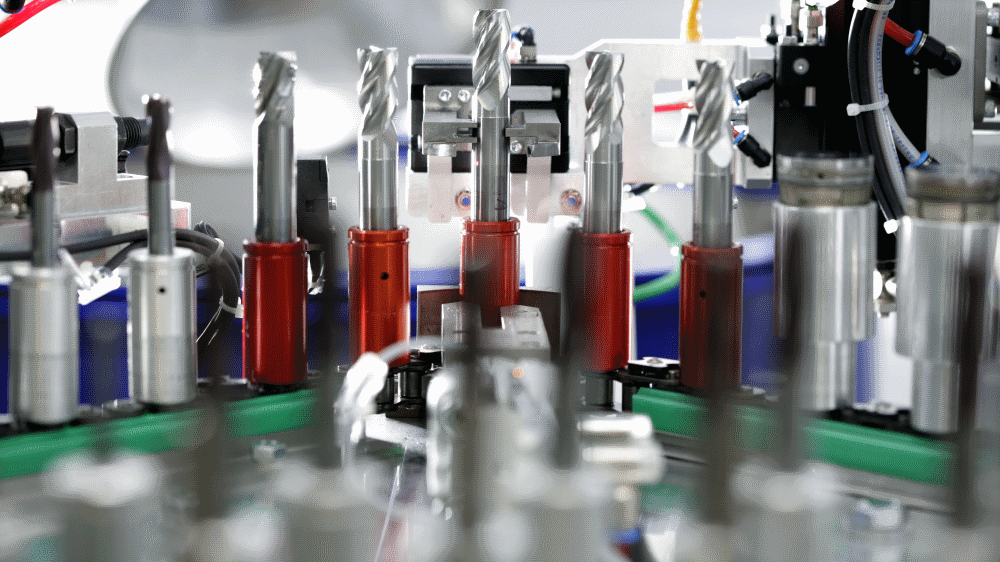

Automatischer Werkstückwechsel mittels Kettenlader © OTEC Präzisionsfinish GmbH

Automatischer Werkstückwechsel mittels Kettenlader © OTEC Präzisionsfinish GmbH

The quality of stamping, forming and cutting tools can be improved considerably by finishing in the DF and SF machines from OTEC. Smoothing, polishing, edge rounding, deburring and removing droplets are typical finishing tasks which produce a dramatic improvement in workpieces.

The DF Tools series of drag finishing machines with manual loading and unloading are ideally suited for this area of application. The new, integrated automatic door enables workpieces to be changed even faster than ever.

Especially when a company grows in size and the number of items to be produced increases, a fast and efficient finishing system becomes more and more important.

With the SF1-Automation with chain loader, OTEC sets a new standard in automated precision finishing.

This machine is specially tailored to the requirements of the toolmaking industry and its automated loading system delivers clear cost benefits.

The SF1-Automation features a chain loader with 64 positions in loading sleeves that can vary according to the diameter of the tools.

The machine can process different tools ranging between 3 and 32 mm in diameter in a single batch. This is achieved by automatically changing the workpiece and chuck adapter as required.

When the finishing process is complete, the tools are returned to their loading sleeves. Tool change time is approx. 14.5 seconds.

Depending on the finishing process and the tool geometry, processing times are between 30 and 300 seconds.

The SF1-Automation is equipped with a lifting unit for incoming tools and is suitable for both wet and dry finishing.

Source: OTEC Präzisionsfinish GmbH