Morgan Advanced Materials improves materials and processes

© Morgan Advanced Materials

© Morgan Advanced Materials

Morgan Advanced Materials has improved its material development and manufacturing capabilities, in response to growing demand for ultrasonic flow and level measurement solutions which are able to withstand the demands of the Liquefied National Gas (LNG) industry.

Recent improvements to its portfolio of materials and assembly processes have resulted in a number of key performance advantages, including enhanced resistance to thermal shock and full functionality and measurement accuracy at pressures of up to 10bar. The latest sensor offerings from Morgan can also withstand multiple immersions in liquid nitrogen from ambient temperatures, with minimal impact on performance.

The LNG market is currently entering a period of rapid expansion, with one recent estimate from TechSci Research indicating that the market is set to grow at CAGR of 5% until 2025. In view of this, demand for cryogenic sensing in LNG applications is also expected to grow substantially over the next few years. As a leading name in sensor and transducer technology, developments within Morgan Advanced Materials mean that it can now offer solutions based on ultrasonic technology, which are even better suited to the challenges associated with cryogenic flow measurement.

Charles Dowling, Business Development Manager at Morgan Advanced Materials, explained: "We have the capability to deliver bespoke solutions to meet the precise specification requirements of our customers. Our best in class solutions are based on our world-leading understanding of piezoelectric materials and component manufacturing processes. Drawing on our extensive prototyping capability, we can provide a comprehensive design and production service for challenging materials and technologies used in transducer and sensing applications."

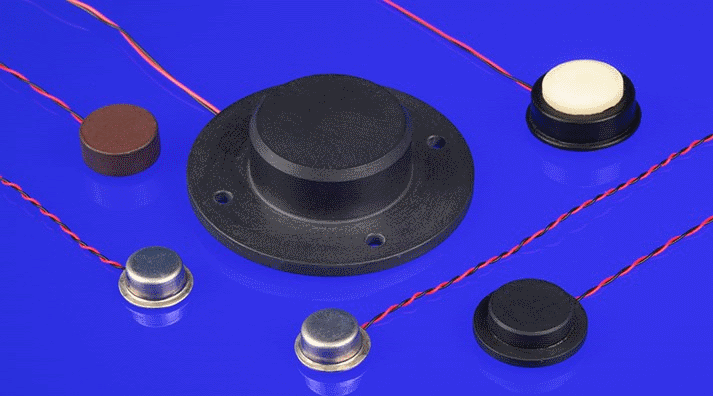

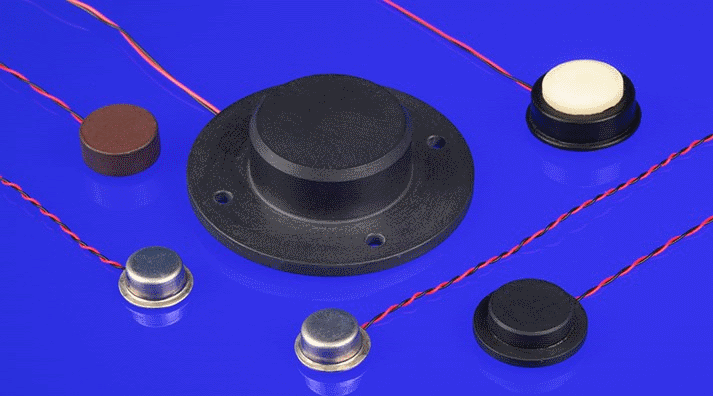

Morgan can offer sensors in a range of fully-customisable configurations, starting from 1.25cm (0.5 inch) in diameter, which can typically operate within a frequency range of 50 kHz to 2 MHz. Available housing materials include titanium and stainless steel as standard, with a range of alternative materials available on request, depending on the customer's application.

Ultrasonic sensors present several advantages over alternative technologies. They are largely immune to changes in liquid dielectric properties and offer greater reliability and accuracy over time due to the absence of moving parts.

Source: Morgan Advanced Materials

© Morgan Advanced Materials

© Morgan Advanced Materials